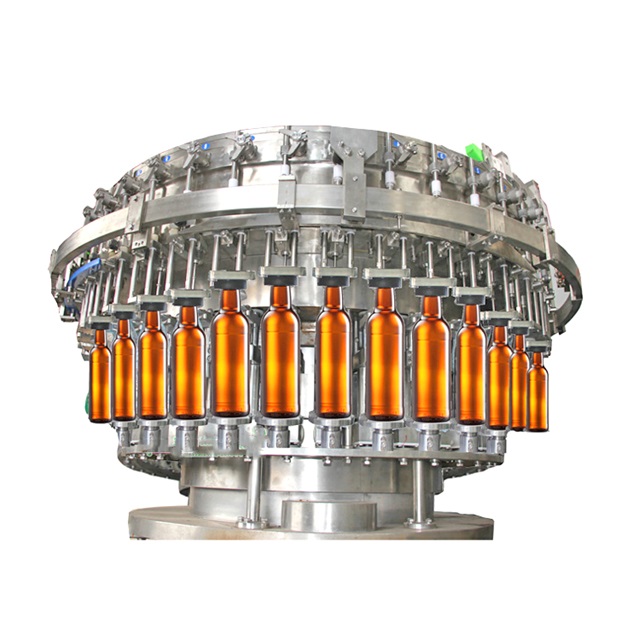

Igwe na-ejuputa igwe na-emepụta Line

Igwe ndochi nwere ọrụ nke imechi valves ndochi mgbe enwere karama gbajiri agbaji, na ịsacha karama gbajiri agbaji. Ọkpụkpọ ikuku nwere ngwaọrụ na-ewepụ ụfụfụ akpaka. The aghụghọ okpu-unscrambling na okpu imewe na-ebufe ihe nchebe na ọrụ zuru ezu. Ọ bụ PLC na-achịkwa ya.

Uru:

A) PLC na ihuenyo mmetụ aka zuru oke njikwa. Ọ dị mfe ịrụ ọrụ.

B) Ndochi ngwa ngwa maka mgbanwe nha karama dị iche iche.

C) Nhazi nkenke, nke a pụrụ ịdabere na ya na nke dịgidere, dị mfe ịnọgide na-enwe.

Isi atụmatụ

1) Igwe nchacha na-eji karama igwe anaghị agba nchara dị elu nke nchekwa nchekwa mmiri, iji hụ na ngbanwe nke karama iko ahụ kwụsiri ike.

2) Igwe na-ejuputa igwe nwere ụdị akụrụngwa na-ebuli elu nke mmiri iji bulite karama iko, nnukwu nkwado na-efe efe na vat na iji ntuziaka-mkpanaka na nhazi nke ihe owuwu ahụ, enwere atụmatụ mkpuchi tupu.

3) Jiri valvụ na-ejuputa igwe dị elu, yana ọkwa mmiri mmiri cylinder. A na-achịkwa nrụgide azụ site na mgbama agbanwe nha nhata. Ọsọ, kwụsie ike, ziri ezi, oghere otu n'otu oge.

4) Tupu capping, na-eji mmiri ọkụ afụ setịpụ na-ewepụ ikuku nke bottlenecks, n'ịhụ na oxygen ọdịnaya nke na-erughị 0.15mg/l.

5) Igwe na-ejuputa na-agụnye karama gbajiri agbaji na-akwụsị valvụ na-akpaghị aka, ịsacha karama gbajiri agbaji, na ụfụfụ na-agwụ ngwa ngwa.

6) Site na ọrụ nhicha CIP zuru oke, ma nwee ike kpochaa ọkpọkọ na-ejuputa na acid, lye mmiri mmiri na mmiri ọkụ.

7) Ihe niile dị na kọntaktị na valves, tankị, ọkpọkọ na-eji igwe anaghị agba nchara 304. N'ime na n'èzí mgbidi ka a na-egbu maramara iji hụ na ahụike dị mma.

8) The dum ọrụ adopts elu mmadụ-igwe interface, PLC akara, ugboro ntụgharị stepless ọsọ ụkpụrụ na ndị ọzọ na akpaka akara technology. Na-enweghị karama enweghị oghere oghere na enweghị stamping, enweghị okpu enweghị ọrụ, yana nchekwa nchekwa ndị ọzọ.